Geotextiles are a cornerstone of modern engineering and environmental management, playing a vital role in construction, landscaping, and water management. They serve as barriers, filters, and reinforcements, often operating in challenging conditions where durability and functionality are paramount.

But a critical question many professionals and enthusiasts ask is: Is geotextile permeable? The answer can shape your choice of materials and ensure your project achieves its intended purpose.

Geotextiles are specially engineered fabrics used in construction, landscaping, and environmental protection projects. They are designed to perform a range of functions like separation, filtration, drainage, and reinforcement, making them indispensable in infrastructure and civil engineering.

Definition and Purpose

A geotextile is a synthetic fabric made from materials like polypropylene or polyester. These fabrics are manufactured to provide structural support, enhance drainage, and protect soil integrity in various applications. Their primary functions include:

- Separation: Preventing the intermixing of different soil layers.

- Filtration: Allowing water to pass through while retaining soil particles.

- Drainage: Facilitating the movement of fluids to prevent waterlogging.

- Reinforcement: Providing additional strength to soils and structures.

Types of Geotextiles

Geotextiles come in three main types, each designed for specific tasks:

- Woven Geotextiles

- Created by weaving synthetic fibers together, offering high tensile strength.

- Best for applications requiring soil stabilization, such as road construction.

- Non-Woven Geotextiles

- Manufactured by bonding fibers using heat, chemical processes, or needle punching.

- Known for their permeability, making them ideal for filtration and drainage.

- Knitted Geotextiles

- Made by interlocking loops of yarn, a less common type with specialized applications.

Materials Used in Geotextiles

The most commonly used materials include:

- Polypropylene (PP): Lightweight, durable, and resistant to chemical degradation.

- Polyester (PET): Offers greater strength and resistance to UV rays.

- Natural Fibers: Occasionally used in temporary applications like erosion control.

Each material has unique properties that influence its suitability for specific projects. For instance, polypropylene is highly resistant to moisture, making it a preferred choice for drainage applications.

Common Applications of Geotextiles

Geotextiles are used across a wide array of industries:

- Road Construction: To prevent soil migration and enhance stability.

- Erosion Control: Protecting slopes and shorelines from soil loss.

- Drainage Systems: Facilitating the removal of excess water in infrastructure.

- Landfills: Acting as barriers and drainage layers.

- Agriculture: Enhancing soil retention and water filtration.

By understanding what geotextiles are and how they work, you can appreciate their role in addressing various engineering and environmental challenges.

Understanding Permeability in Geotextiles

The concept of permeability is central to the functionality of geotextiles. Whether a geotextile is permeable or impermeable can determine its effectiveness in specific applications, from drainage systems to erosion control. Let’s explore what permeability means in this context and why it is such an essential consideration.

What Does Permeability Mean?

In simple terms, permeability refers to the ability of a material to allow fluids or gases to pass through it. When applied to geotextiles, permeability primarily concerns the flow of water.

Permeable geotextiles permit water to move through their fabric while filtering out particles such as soil or sediment. This capability is particularly valuable in applications where water management and soil retention are critical, such as drainage systems or erosion control measures.

Why Does Permeability Matter in Geotextiles?

The permeability of a geotextile directly impacts its performance in various functions:

- Drainage Efficiency: Highly permeable geotextiles ensure that water is removed from an area quickly, preventing waterlogging.

- Filtration: Maintaining soil integrity while allowing water to escape is vital for many construction and environmental projects.

- Structural Stability: Managing water flow reduces pressure buildup in soils, which can otherwise compromise structural stability.

Without the right level of permeability, a geotextile could fail to perform its intended purpose, leading to issues like clogged drainage systems or soil erosion.

Permeability in Geotextiles: Key Factors

Several factors influence the permeability of a geotextile, including:

- Material Composition

- Synthetic fibers like polypropylene and polyester are designed to resist water absorption while still allowing flow.

- The choice of material affects the pore size and filtration capability of the fabric.

- Fabric Type

- Woven geotextiles tend to have lower permeability due to their tightly woven structure. They are better suited for stabilization rather than drainage.

- Non-woven geotextiles are more permeable, as their porous structure facilitates water flow, making them ideal for filtration and drainage tasks.

- Pore Size and Filtration Efficiency

- The size of the openings in the fabric determines how well it can filter particles while permitting fluid flow.

- Small pore sizes enhance filtration but may reduce the rate of water flow, while larger pores allow faster drainage but may let some particles pass.

- Thickness of the Fabric

- Thicker geotextiles can impede water flow, making thinner variants more suitable for high-permeability applications.

Real-World Importance of Geotextile Permeability

To illustrate the importance of permeability, consider the example of a drainage trench in a roadway. A non-woven geotextile with high permeability ensures water flows into the drainage system while preventing soil particles from clogging it. In contrast, a less permeable woven geotextile could slow water drainage, leading to pooling or erosion issues.

In another scenario, an impermeable geotextile might be required to line a waste containment facility, preventing any liquids from seeping into the surrounding environment.

Testing Geotextile Permeability

Geotextiles undergo rigorous testing to determine their permeability. Common methods include:

- Permittivity Tests

- Measures the volume of water that passes through the fabric under standard conditions.

- Hydraulic Conductivity Tests

- Evaluates the ease with which water flows through the geotextile under pressure.

These tests ensure the geotextile meets the specifications required for its intended use.

Are Geotextiles Permeable?

The answer to whether geotextiles are permeable depends on their type and intended application. While many geotextiles are designed to be permeable, facilitating water and air flow, others are deliberately made impermeable to serve as effective barriers. Let’s dive deeper into how geotextiles function in terms of permeability and their specific use cases.

Short Answer: It Depends

Geotextiles can be either permeable or impermeable, and the choice depends on their material, manufacturing process, and intended use. Permeable geotextiles are most commonly used in drainage, filtration, and erosion control, allowing fluids to pass through while filtering out soil particles. On the other hand, impermeable geotextiles or geomembranes are used in applications like containment systems, where fluid movement must be completely blocked.

How Material and Application Influence Permeability

- Woven Geotextiles

- Permeability: Limited due to their tightly woven structure.

- Best Uses: Soil stabilization, separation, and reinforcement.

- Example: Road base stabilization, where preventing soil mixing is key.

- Non-Woven Geotextiles

- Permeability: High, thanks to their porous structure.

- Best Uses: Filtration, drainage, and erosion control.

- Example: Drainage layers under roads to allow water flow while preventing soil migration.

- Impermeable Geotextiles (Geomembranes)

- Permeability: None; these are designed to act as a complete barrier.

- Best Uses: Containment systems for hazardous waste or pond linings.

- Example: Landfill liners to prevent leachate from contaminating groundwater.

Case Study: Permeable Geotextiles in Action

A notable example of permeable geotextiles is their use in highway drainage systems. Here’s how they function:

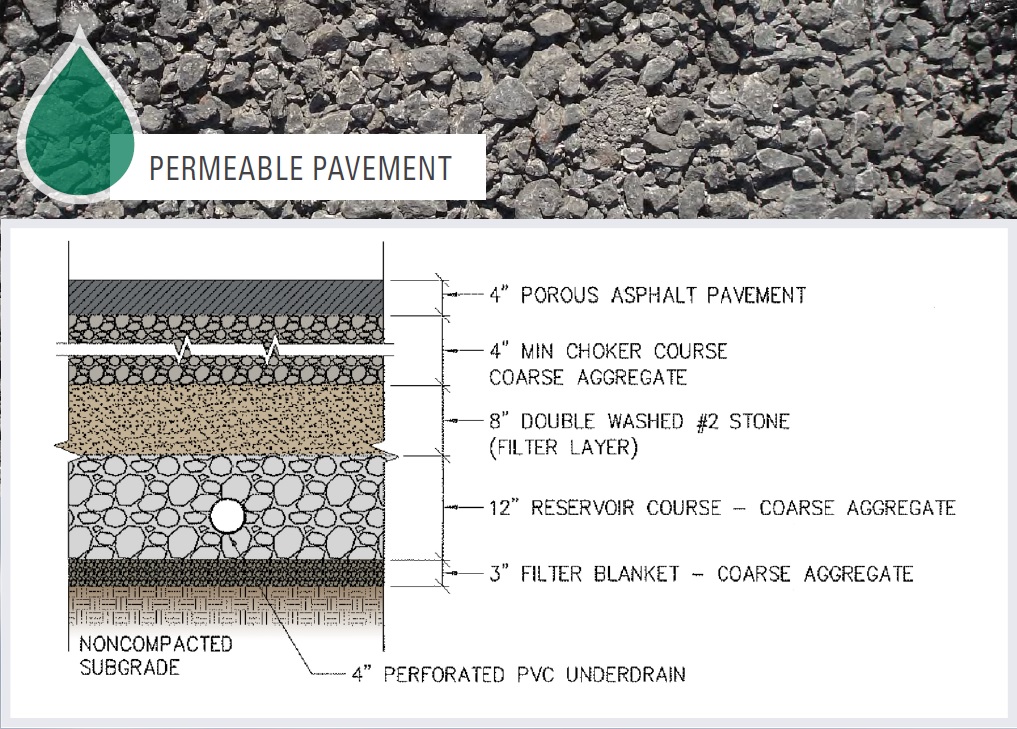

- A non-woven geotextile is laid beneath the gravel layer to allow water to drain from the road surface into the drainage system.

- The geotextile filters out fine soil particles, preventing them from clogging the gravel or pipes below.

- This setup not only improves the lifespan of the road but also ensures efficient water management during heavy rains.

The success of these systems depends entirely on the geotextile’s permeability and its ability to balance water flow with filtration.

Testing Geotextile Permeability

Before a geotextile is selected for a project, its permeability is tested to ensure it meets specific requirements. Two common testing methods include:

- Permittivity Tests

- Measures the rate at which water flows through the geotextile under standard conditions.

- Expressed in units of flow rate per unit thickness.

- Hydraulic Conductivity Tests

- Assesses how easily water flows through the fabric when subjected to pressure.

- Particularly important for drainage and filtration applications.

These tests help engineers ensure the geotextile is fit for its intended purpose, minimizing risks like clogging or insufficient water flow.

Permeable vs. Impermeable Geotextiles

| Feature | Permeable Geotextiles | Impermeable Geotextiles |

|---|---|---|

| Material | Non-woven polypropylene or polyester | Laminated or coated synthetic materials |

| Permeability | Allows water and air flow | Blocks all fluid movement |

| Applications | Drainage, filtration, erosion control | Containment systems, pond liners, landfill caps |

| Example Projects | Highway drainage, soil stabilization | Hazardous waste containment, aquaculture ponds |

By understanding whether a geotextile is permeable or impermeable, you can determine its suitability for your specific project needs.

Applications of Permeable Geotextiles

Permeable geotextiles play an essential role in various engineering and environmental projects, thanks to their ability to allow water to pass through while maintaining soil stability. From facilitating drainage to protecting against erosion, these fabrics offer versatile solutions for complex challenges.

Let’s explore the key applications of permeable geotextiles and how they enhance the performance of infrastructure and environmental projects.

Drainage Systems

One of the most common uses of permeable geotextiles is in drainage systems. These fabrics enable water to flow through while filtering out soil and sediment, ensuring the long-term efficiency of drainage infrastructure.

Key Examples:

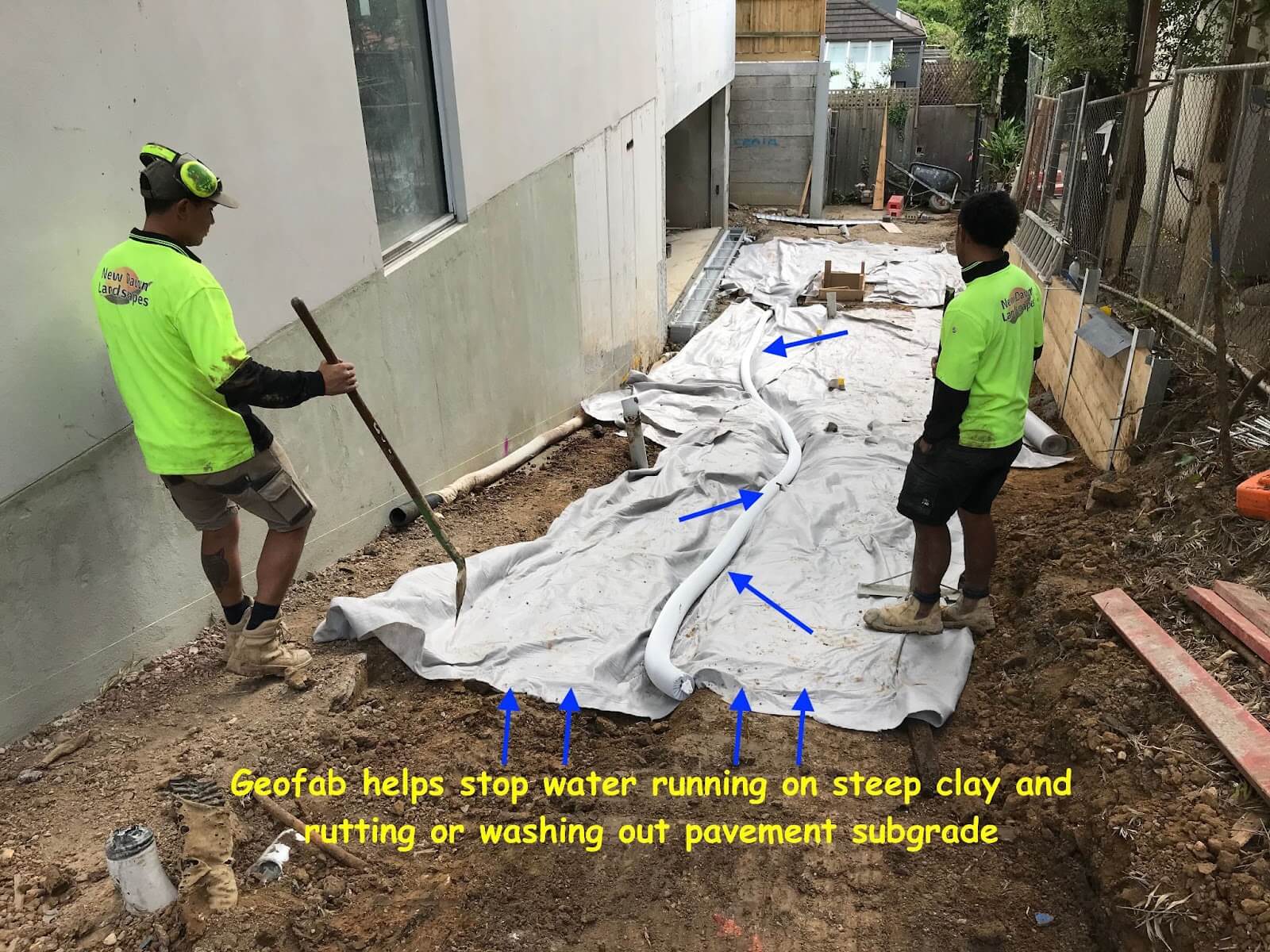

- Roadway Drainage: Non-woven geotextiles are placed beneath road surfaces to direct water into drainage channels, reducing the risk of water pooling and road damage.

- Subsurface Drains: In fields or residential areas, permeable geotextiles surround perforated pipes to prevent soil infiltration while maintaining water flow.

Benefits of Geotextiles in Drainage Systems:

- Prevent clogging of drainage pipes and systems.

- Enhance the lifespan and performance of drainage infrastructure.

- Minimize soil erosion and sediment deposition.

Case Study: In a highway construction project, a non-woven geotextile was used under the pavement to facilitate water drainage. The result was a significant reduction in water-induced road failures, highlighting the geotextile’s role in extending the lifespan of the road.

Filtration

Permeable geotextiles excel in filtration applications by retaining soil particles while allowing water to flow through. This property makes them invaluable in projects where soil stability and water management must coexist.

Applications in Filtration:

- Retaining Walls: Geotextiles are used to filter water behind retaining walls, preventing soil from being washed out while relieving hydrostatic pressure.

- Earth Embankments: Geotextiles filter seepage water, protecting the structure’s integrity.

Advantages of Using Geotextiles for Filtration:

- Maintain soil strength while managing water flow.

- Prevent clogging and reduce maintenance needs.

- Offer a cost-effective and long-lasting solution.

Interesting Fact: Non-woven geotextiles often have pore sizes designed to match specific soil types, ensuring optimal filtration without compromising water flow.

Erosion Control

Permeable geotextiles are widely used to control erosion on slopes, riverbanks, and coastal areas. By stabilizing soil and regulating water movement, they prevent soil loss and protect ecosystems.

Erosion Control Techniques Using Geotextiles:

- Slope Protection: Geotextiles are laid over slopes to secure soil, especially in areas with heavy rainfall.

- Riverbank Stabilization: Placed under riprap (rocks), geotextiles prevent soil from washing away during high water flows.

- Coastal Applications: Non-woven geotextiles are used in dunes and beaches to minimize erosion caused by waves and tides.

Real-World Example: In a coastal protection project, non-woven geotextiles were installed beneath a layer of sand and vegetation. Over time, they significantly reduced erosion, preserving the coastline and reducing maintenance costs.

Additional Applications of Permeable Geotextiles

- Agricultural Drainage: Facilitates water movement in fields, preventing waterlogging while maintaining soil fertility.

- Green Roofs: Enhances drainage and filtration in urban landscapes, supporting vegetation while managing runoff.

- Playgrounds and Sports Fields: Improves water drainage, preventing muddy conditions and ensuring usability.

Versatility of Permeable Geotextiles in Applications

The use of permeable geotextiles in these applications highlights their critical role in managing water, soil, and environmental conditions effectively. Their ability to combine filtration with drainage and erosion control makes them indispensable in modern construction and environmental management.