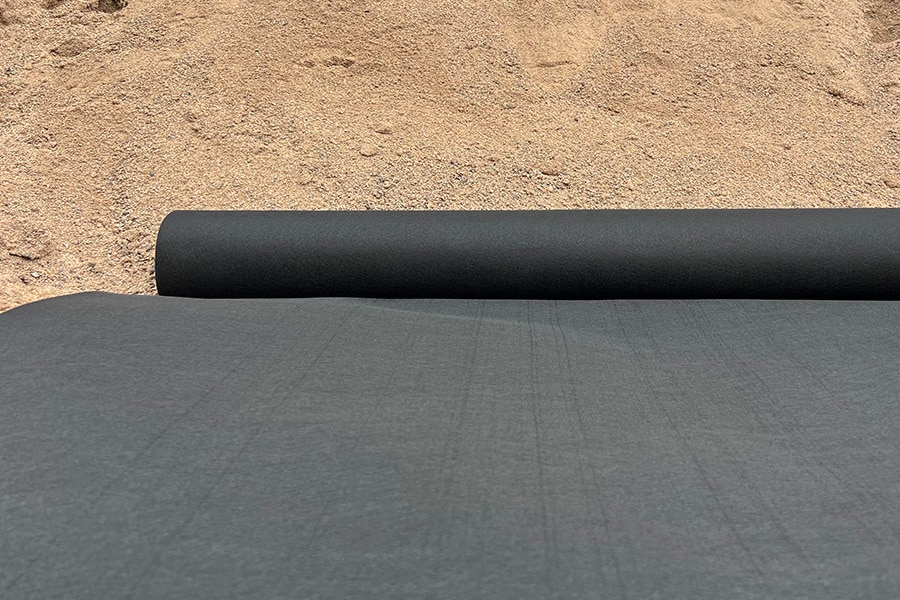

Geotextiles are specialized fabrics used in various civil engineering and landscaping applications. Made from synthetic or natural fibers, these materials are designed to perform specific functions such as separation, filtration, reinforcement, protection, or drainage. Geotextiles play a crucial role in enhancing the stability and longevity of infrastructure projects by addressing issues related to soil erosion, water flow, and material separation.

Common Materials Used in Geotextiles:

- Polypropylene: Known for its durability and resistance to chemicals, making it ideal for drainage and separation tasks.

- Polyester: Offers high tensile strength and UV resistance, suitable for applications requiring long-term stability.

- Natural Fibers: Such as jute or coir, used primarily in temporary applications like erosion control where biodegradability is desired.

Common Uses of Geotextiles

Geotextiles are versatile materials utilized in a wide range of applications across different industries. Understanding these uses helps in appreciating their value and assessing whether geotextile is expensive relative to the benefits they provide.

1. Road Construction: Geotextiles are employed in road building to separate the subgrade from the aggregate base, preventing mixing of materials. This separation enhances load distribution, reduces maintenance costs, and extends the lifespan of the roadway.

2. Erosion Control: In areas prone to soil erosion, geotextiles provide a protective barrier that stabilizes the soil, especially on slopes and embankments. They help retain soil structure during heavy rains and wind, minimizing environmental degradation.

3. Landscaping and Gardening: Garden projects often use geotextiles to improve drainage, prevent weed growth, and maintain soil integrity. By laying a geotextile fabric beneath mulch or soil, gardeners can achieve cleaner, more sustainable landscapes with less maintenance.

4. Drainage Systems: Geotextiles facilitate efficient water flow in drainage applications by acting as filters that prevent soil particles from clogging drainage pipes or systems. This ensures effective water management in areas like retaining walls, parking lots, and agricultural fields.

5. Reinforcement: In construction projects, geotextiles reinforce structures by distributing loads more evenly and enhancing the tensile strength of the soil. This is particularly important in the construction of retaining walls, embankments, and other earth-moving projects.

6. Environmental Protection: Geotextiles are used in environmental projects to contain hazardous materials, prevent contamination, and support the restoration of natural habitats. They serve as barriers in landfills, protecting surrounding soil and water sources from pollutants.

By integrating geotextiles into these applications, engineers, contractors, and homeowners can achieve more durable and cost-effective solutions. While the initial investment in geotextiles may raise the question, is geotextile expensive, the long-term benefits and savings often justify the cost.

When evaluating is geotextile expensive, it’s essential to delve into the factors that influence their pricing. Understanding these elements can help you make informed decisions and determine whether geotextiles are a cost-effective solution for your specific project needs.

What Determines the Price of Geotextiles?

The cost of geotextiles can vary significantly based on several key factors. Here’s a detailed look at what influences their pricing:

- Material Quality and Type:

- Synthetic Fibers: Geotextiles made from high-quality synthetic materials like polypropylene and polyester tend to be more expensive due to their durability and performance characteristics.

- Natural Fibers: Options like jute or coir are generally less costly but may have shorter lifespans and are suitable for temporary applications.

- Manufacturing Processes:

- Advanced manufacturing techniques that enhance the strength, permeability, and longevity of geotextiles can increase production costs. Innovations such as needle-punching or thermal bonding contribute to higher prices but offer better performance.

- Thickness and Weight:

- Thicker and heavier geotextiles provide greater strength and durability, making them suitable for more demanding applications. These specifications naturally result in higher costs compared to lighter, thinner fabrics.

- Permeability and Pore Size:

- Geotextiles with specific permeability ratings and pore sizes tailored for particular drainage or filtration needs can affect pricing. Custom specifications often come at a premium.

- Brand and Supplier Reputation:

- Established brands known for quality and reliability may charge higher prices. However, investing in reputable suppliers ensures you receive products that meet industry standards and perform as expected.

- Quantity Purchased:

- Buying in bulk typically reduces the unit price of geotextiles. Large projects that require substantial quantities can benefit from economies of scale, making geotextiles more affordable per unit.

- Geographical Location:

- Shipping costs and regional availability can influence the final price of geotextiles. In areas where geotextiles are less common, transportation costs may drive up prices.

Price Range for Different Types of Geotextiles

Geotextiles come in various types, each with its own price range based on the factors mentioned above. Here’s a breakdown of typical costs:

| Type of Geotextile | Price Range (per square meter) | Characteristics |

|---|---|---|

| Woven Geotextiles | $2 – $6 | High tensile strength, suitable for reinforcement |

| Non-Woven Geotextiles | $1.50 – $5 | Excellent filtration and drainage properties |

| Biodegradable Geotextiles | $1 – $4 | Made from natural fibers, suitable for temporary use |

| High-Performance Geotextiles | $5 – $12 | Enhanced durability and specialized functions |

Woven vs. Non-Woven Geotextiles:

- Woven Geotextiles are typically more expensive due to their robust construction, making them ideal for heavy-duty applications like road reinforcement.

- Non-Woven Geotextiles are generally more affordable and excel in drainage and filtration tasks, offering versatility across various projects.

Synthetic vs. Natural Fiber Geotextiles:

- Synthetic Geotextiles command higher prices but offer superior longevity and performance, especially in harsh environmental conditions.

- Natural Fiber Geotextiles are cheaper and environmentally friendly but are best suited for short-term applications due to their biodegradability.

Cost Comparison: Geotextiles vs. Traditional Materials

One common question when assessing is geotextile expensive is how their costs stack up against traditional materials used for similar applications. Here’s a comparative analysis:

| Application | Geotextiles Cost | Traditional Material Cost | Additional Considerations |

|---|---|---|---|

| Road Construction | $2 – $6/m² | Gravel: $1 – $3/m² | Geotextiles enhance durability and reduce maintenance costs |

| Erosion Control | $1 – $4/m² | Mulch/Rock: $0.50 – $2/m² | Geotextiles provide longer-lasting soil stabilization |

| Landscaping/Gardening | $1.50 – $5/m² | Weed Barrier Paper: $0.30 – $1/m² | Geotextiles offer better durability and drainage |

| Drainage Systems | $2 – $5/m² | Gravel/Ditches: Variable | Geotextiles ensure efficient filtration and prevent clogging |

| Retaining Walls | $3 – $7/m² | Concrete Reinforcement: Higher | Geotextiles can reduce the need for extensive concrete use |

- Initial Costs: Geotextiles may have higher upfront costs compared to some traditional materials like gravel or mulch.

- Long-Term Savings: The durability and performance of geotextiles can lead to significant savings over time by reducing maintenance, preventing material mixing, and enhancing the lifespan of projects.

- Performance Benefits: Geotextiles often provide superior functionality, such as better drainage and soil stabilization, which traditional materials may not achieve as effectively.

Case Study Example: A road construction project initially considered using gravel for base separation. However, by opting for woven geotextiles at an additional cost of $3/m², the project achieved a 30% reduction in maintenance expenses over five years due to improved load distribution and reduced material mixing.

While geotextiles may seem more expensive at first glance, their long-term benefits and cost-effectiveness often outweigh the initial investment, especially in projects where durability and performance are critical.

Is Geotextile Expensive? Analyzing the Value

When considering is geotextile expensive, it’s crucial to look beyond the initial cost and evaluate the overall value they bring to your projects. Geotextiles offer numerous long-term benefits that can make them a cost-effective choice in the long run.

Long-Term Benefits of Using Geotextiles

Geotextiles provide several long-term advantages that enhance the durability and functionality of construction and landscaping projects. Understanding these benefits can help you appreciate why geotextile is expensive but also valuable.

- Durability and Lifespan:

- Enhanced Longevity: High-quality geotextiles can last for decades without significant degradation, even in harsh environmental conditions. This durability reduces the need for frequent replacements, saving money over time.

- Resistance to Environmental Factors: Geotextiles are designed to withstand UV radiation, chemicals, and physical stress, ensuring they maintain their integrity and performance throughout their lifespan.

- Maintenance Savings:

- Reduced Maintenance Needs: By preventing soil erosion, managing drainage, and separating materials, geotextiles minimize the need for ongoing maintenance and repairs. This reduction in maintenance can lead to substantial cost savings.

- Less Frequent Repairs: Projects that utilize geotextiles are less likely to experience issues like soil mixing or water clogging, which often require costly repairs when using traditional materials.

- Improved Performance:

- Better Load Distribution: In applications like road construction, geotextiles distribute loads more evenly, reducing stress on underlying materials and preventing premature wear and tear.

- Effective Drainage: Geotextiles facilitate efficient water flow, preventing water accumulation and related damage, which is particularly beneficial in drainage systems and retaining walls.

- Environmental Benefits:

- Erosion Control: Geotextiles play a significant role in preventing soil erosion, protecting the environment, and maintaining the stability of landscapes and infrastructure.

- Sustainable Solutions: Many geotextiles are made from recyclable or biodegradable materials, contributing to environmentally friendly construction practices.

Cost-Effectiveness Over Time

While the initial investment in geotextiles might be higher compared to some traditional materials, their cost-effectiveness over time makes them a smart financial choice. Here’s how geotextiles prove to be economical in the long term:

- Initial Investment vs. Long-Term Savings:

- Higher Upfront Costs: Geotextiles may cost more initially, but their durability and performance reduce the need for future expenditures on maintenance and replacements.

- Extended Project Lifespan: Projects that incorporate geotextiles typically last longer, delaying the costs associated with rebuilding or extensive repairs.

- Preventative Benefits Reducing Future Costs:

- Avoiding Structural Failures: By providing essential functions like soil stabilization and effective drainage, geotextiles help prevent structural failures that can lead to expensive repairs.

- Minimizing Material Degradation: Geotextiles protect underlying materials from degradation caused by water, soil movement, and other environmental factors, preserving the integrity of the entire structure.

- Energy and Resource Efficiency:

- Lower Resource Consumption: The use of geotextiles can reduce the amount of other materials needed, such as gravel or concrete, leading to cost savings on material purchases.

- Efficient Installation: Geotextiles can simplify installation processes, potentially lowering labor costs and reducing the time required to complete projects.

Return on Investment for Geotextile Applications

Investing in geotextiles can yield significant returns, both financially and in terms of project performance. Understanding the return on investment (ROI) can help you make informed decisions about incorporating geotextiles into your projects.

- Case Studies Showcasing ROI:

- Road Construction Example:

- Project Overview: A municipal road project initially planned to use traditional gravel separation.

- Geotextile Implementation: Switched to woven geotextiles at an additional cost of $3/m².

- Results: Over five years, maintenance costs decreased by 30%, and road longevity improved by 25%, leading to overall savings and a higher ROI.

- Erosion Control in Coastal Areas:

- Project Overview: A coastal development faced severe erosion issues.

- Geotextile Solution: Installed non-woven geotextiles to stabilize the soil.

- Results: Erosion rates dropped by 50%, reducing the need for frequent repairs and safeguarding property investments.

- Road Construction Example:

- Industry Testimonials:

- Construction Companies:

- Many construction firms report that using geotextiles has streamlined their projects, reduced long-term costs, and enhanced the quality and durability of their work.

- Landscaping Professionals:

- Landscape architects and gardeners appreciate geotextiles for their ability to maintain soil integrity and manage drainage effectively, leading to healthier and more sustainable landscapes.

- Construction Companies:

- Financial Metrics:

- Payback Period: The time it takes for the savings generated by using geotextiles to cover the initial investment is often shorter than expected, especially in large-scale projects.

- Net Present Value (NPV): The long-term benefits of geotextiles contribute to a positive NPV, indicating that the investment adds value over time.

- Enhanced Property Value:

- Projects that utilize geotextiles often result in higher quality and more durable infrastructure, which can increase the overall value of the property or development.

Summary of Value Analysis

When evaluating is geotextile expensive, it’s essential to consider the comprehensive value they offer:

- Long-Term Durability: Reduces the need for frequent replacements and repairs.

- Maintenance Savings: Lowers ongoing maintenance costs by enhancing project stability and performance.

- Enhanced Performance: Improves load distribution, drainage, and erosion control, leading to more reliable and resilient structures.

- Environmental Benefits: Supports sustainable construction practices and protects natural resources.

- Positive ROI: Provides significant financial returns through cost savings and increased property value.

While geotextiles may have a higher initial cost, their numerous long-term benefits and cost-effectiveness make them a valuable investment for various construction and landscaping projects. By carefully assessing your project requirements and understanding the value that geotextiles bring, you can make informed decisions that balance cost with performance and durability.

Factors Influencing Geotextile Costs

When assessing is geotextile expensive, it’s important to understand the various factors that influence their pricing. These factors not only affect the cost of geotextiles but also determine their suitability for different applications. By comprehensively evaluating these elements, you can make informed decisions that align with your project’s budget and performance requirements.

Material and Manufacturing Quality

Material quality and manufacturing processes play a pivotal role in determining the cost of geotextiles. Higher-quality materials and advanced manufacturing techniques typically result in more expensive products, but they also offer enhanced performance and durability.

- Material Types:

- Synthetic Fibers: Geotextiles made from synthetic materials like polypropylene and polyester are generally more costly due to their superior strength, longevity, and resistance to environmental factors. These materials are ideal for heavy-duty applications such as road construction and soil reinforcement.

- Natural Fibers: Geotextiles composed of natural fibers like jute or coir are usually less expensive. They are suitable for temporary applications like erosion control where biodegradability is an advantage, but they may not offer the same durability as synthetic options.

- Manufacturing Processes:

- Woven vs. Non-Woven: Woven geotextiles are created by interlacing fibers, resulting in higher tensile strength and durability, which increases their cost. Non-woven geotextiles, produced through methods like needle-punching or thermal bonding, are generally more affordable and excel in filtration and drainage applications.

- Advanced Techniques: Processes such as thermal bonding or needle-punching enhance the properties of geotextiles, making them more effective but also more expensive. These advanced manufacturing techniques ensure that the geotextiles meet specific performance standards required for challenging environments.

- Quality Standards:

- Certifications and Compliance: Geotextiles that adhere to international quality standards and certifications (e.g., ISO, ASTM) often command higher prices. Compliance ensures that the products meet stringent performance criteria, providing assurance of their effectiveness and reliability.

Impact on Cost:

- High-Quality Materials and Advanced Manufacturing: These factors contribute to higher production costs, which are reflected in the final price of the geotextile. However, the enhanced performance and longevity can justify the additional expense by reducing the need for replacements and maintenance.

Thickness, Weight, and Durability

The thickness, weight, and durability of geotextiles are critical specifications that influence both their cost and their suitability for specific applications. Understanding these attributes helps in selecting the right geotextile for your project, ensuring cost-effectiveness without compromising on performance.

- Thickness:

- Measurement: Typically measured in millimeters (mm), the thickness of a geotextile indicates its density and strength.

- Impact on Cost: Thicker geotextiles require more material and a more intensive manufacturing process, leading to higher costs. For instance, a geotextile with a thickness of 0.5 mm will generally be more expensive than one with 0.2 mm.

- Application Suitability: Thicker geotextiles are preferred for heavy-duty applications like road reinforcement and retaining walls, where higher strength and durability are essential.

- Weight:

- Measurement: Weight is usually specified in grams per square meter (gsm). Higher gsm values indicate denser and stronger geotextiles.

- Impact on Cost: Higher-weight geotextiles are more robust and offer better performance, but they also cost more due to the increased material usage.

- Application Suitability: Projects requiring substantial load-bearing capacity, such as railway construction or large-scale landscaping, benefit from higher-weight geotextiles.

- Durability:

- Factors Influencing Durability: Durability is influenced by the material type, thickness, manufacturing quality, and resistance to environmental factors like UV exposure, chemicals, and physical stress.

- Impact on Cost: More durable geotextiles are priced higher because they offer longer lifespans and better performance under demanding conditions. Investing in durable geotextiles can lead to cost savings over time by reducing the need for frequent replacements and repairs.

- Performance Benefits: Durable geotextiles maintain their structural integrity and functionality over extended periods, ensuring consistent performance in applications such as erosion control, drainage, and reinforcement.

Choosing the Right Specifications:

- Project Requirements: Assess the specific needs of your project, including load-bearing capacity, environmental conditions, and expected lifespan.

- Budget Considerations: Balance the initial cost with long-term benefits. While thicker and heavier geotextiles are more expensive, their durability can result in overall cost savings.

- Supplier Recommendations: Consult with geotextile suppliers or manufacturers to determine the most appropriate specifications for your project’s requirements and budget constraints.

Installation and Labor Costs

The installation and labor costs associated with geotextiles are significant factors that contribute to the overall expense. Proper installation is crucial for maximizing the effectiveness and longevity of geotextiles, but it can also impact the total cost depending on the complexity and labor involved.

- Installation Methods:

- Manual Installation: Involves laying the geotextile by hand, which is suitable for smaller projects like residential landscaping or garden applications. While labor costs are lower, manual installation can be time-consuming and may not be feasible for large-scale projects.

- Mechanical Installation: Utilizes machinery and specialized equipment to lay geotextiles efficiently, making it ideal for extensive projects such as road construction or large erosion control systems. This method reduces installation time but requires access to appropriate machinery, which can increase costs.

- DIY vs. Professional Installation:

- DIY Installation:

- Pros: Lower labor costs and greater control over the installation process.

- Cons: Requires knowledge and experience to ensure proper placement and tensioning. Mistakes can compromise the effectiveness of the geotextile, leading to potential project failures.

- Professional Installation:

- Pros: Ensures accurate and efficient installation by experienced contractors, enhancing the performance and longevity of the geotextile.

- Cons: Higher upfront labor costs, but these can be offset by the reduced risk of installation errors and the assurance of quality workmanship.

- DIY Installation:

- Regional Labor Cost Variations:

- Geographical Differences: Labor costs can vary significantly based on the region, with urban areas typically having higher labor rates compared to rural locations.

- Availability of Skilled Labor: Regions with a higher availability of skilled contractors may offer more competitive pricing, while areas with limited expertise might see increased labor costs.

- Project Accessibility: Difficult-to-reach sites or projects requiring specialized equipment may incur additional labor costs due to the complexity and effort involved in installation.

- Additional Installation Considerations:

- Site Preparation: Proper site preparation, including grading and clearing, is essential for effective geotextile installation. Costs associated with site preparation can add to the overall expense.

- Overlap and Seaming: Ensuring adequate overlap and secure seaming of geotextile layers is crucial for preventing material mixing and maintaining functionality. This requires additional labor and materials, contributing to higher costs.

- Maintenance During Installation: Implementing measures to protect the geotextile during installation, such as temporary supports or protective barriers, can also influence labor costs.

Impact on Overall Cost:

- Complexity and Scale of the Project: Larger and more complex projects naturally incur higher labor costs due to the increased effort and time required for installation.

- Quality of Installation: Investing in professional installation can lead to better project outcomes and long-term cost savings by preventing issues that may arise from improper installation.

Cost-Saving Tips:

- Plan Ahead: Proper planning and site assessment can streamline the installation process, reducing labor time and costs.

- Choose the Right Installer: Hiring experienced and reputable contractors can ensure efficient installation, minimizing the need for rework and additional expenses.

- Bulk Purchasing: Ordering geotextiles in bulk can sometimes include installation services at a discounted rate, lowering overall costs.

Installation and labor costs are integral components of the total expense when evaluating is geotextile expensive. By understanding the factors that influence these costs, such as installation methods, labor rates, and project complexity, you can better budget for your project and explore strategies to optimize expenses without compromising on quality.