Geotextile fabrics are widely used in construction, landscaping, and various civil engineering projects, offering numerous benefits in soil stabilization, drainage, and filtration. However, a common concern that arises with these materials is whether geotextile fabric clogs over time. This is an important question for anyone using or considering geotextile fabrics for drainage or erosion control. If geotextile fabrics clog, their effectiveness in managing water flow, stabilizing soils, and preventing erosion can be compromised, leading to more significant issues down the road.

Geotextile fabric is a synthetic material used in civil engineering, landscaping, and construction. It’s primarily used to separate, filter, reinforce, protect, or drain soil and other materials in a range of projects. Geotextiles are typically made from polypropylene, polyester, or polyethylene and come in different forms—woven, nonwoven, or knitted.

The three main types of geotextile fabric are:

- Woven Geotextiles: Made by interlacing fibers, these fabrics are strong and durable, often used in applications that require heavy load-bearing or reinforcement.

- Nonwoven Geotextiles: Made by bonding fibers together through heat or chemicals, nonwoven geotextiles are used primarily for filtration, drainage, and separation. They are flexible and have excellent permeability.

- Knitted Geotextiles: These are less common but offer a combination of strength and flexibility, mainly used in areas requiring moderate filtration and strength.

Common Uses for Geotextile Fabric

Geotextile fabric is used in a variety of applications across multiple industries. Here are the most common uses:

- Drainage Systems: Geotextile fabrics help water pass through the soil while preventing clogging of drainage pipes or systems.

- Road Construction and Paving: Geotextiles reinforce roadbeds and pavements, providing stability and minimizing erosion.

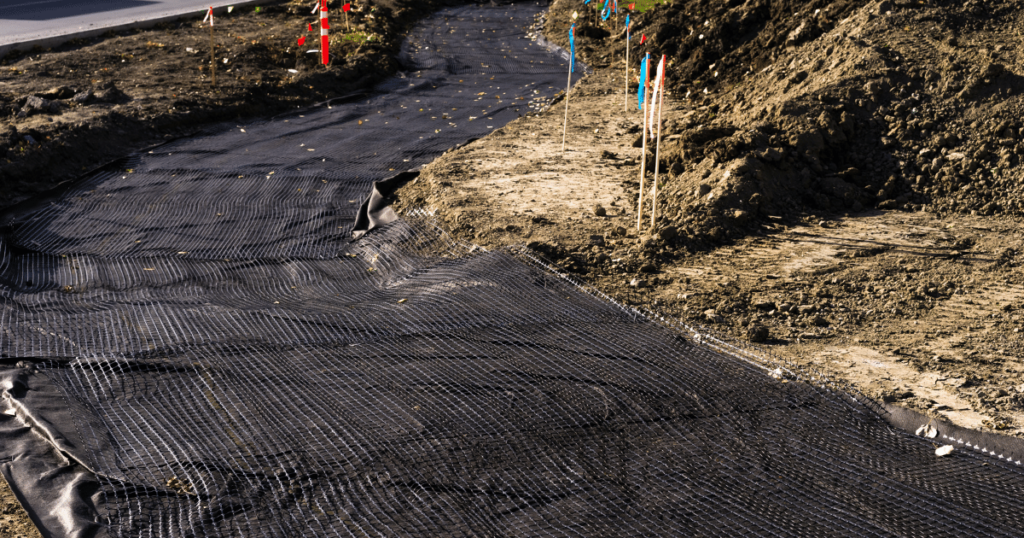

- Erosion Control: Used to prevent soil erosion on slopes, beaches, and embankments, geotextiles hold the soil together while allowing water to pass through.

- Landscaping and Garden Beds: In landscaping, geotextiles prevent weed growth and separate soil layers while ensuring proper water drainage.

How Does Geotextile Fabric Function?

Geotextile fabrics perform a variety of essential functions in construction and landscaping, including:

- Separation: They separate different soil layers, preventing the mixing of fine-grained soils with coarser aggregates or gravel.

- Filtration: Geotextiles allow water to pass through while filtering out harmful particles like silt and debris. This helps maintain proper drainage while keeping the system clear.

- Reinforcement: They provide additional strength and stability to soils or structures, particularly in road and foundation applications.

- Drainage: By promoting the flow of water through soil, geotextile fabrics assist in effective drainage systems that prevent waterlogging and erosion.

Why This Matters for Clogging

Understanding how geotextile fabrics function helps us see how clogging might occur. When fabrics are designed to filter and allow water through, they can be vulnerable to becoming clogged by soil particles, silt, and organic material over time. This is why proper installation and regular maintenance are critical to preventing geotextile fabric clogging.

Does Geotextile Fabric Clog? The Facts Behind Clogging

When considering whether geotextile fabric clogs, it’s important to understand that while geotextile fabrics are designed to allow water flow and filtration, they can indeed become clogged under certain conditions. Clogging is one of the most common concerns for users of geotextile fabrics, especially in drainage and erosion control applications.

Can Geotextile Fabric Become Clogged?

Yes, geotextile fabric can clog, but this typically happens when it is exposed to certain environmental factors or poor maintenance practices. The fabric’s ability to allow water to pass through—its permeability—can be compromised if it becomes obstructed by soil, silt, organic debris, or other particles that build up over time.

While clogging doesn’t necessarily happen immediately, it’s a gradual process that can significantly affect the fabric’s performance in the long term. This is especially true in areas where there is poor drainage, high sediment content in the soil, or heavy organic matter accumulation.

Common Causes of Geotextile Fabric Clogging

Several factors can lead to geotextile fabric clogging:

- Soil Particles: Fine particles, such as silt, clay, and sand, can pass through the fabric and accumulate on its surface or within its fibers. Over time, this build-up restricts the fabric’s permeability and reduces its ability to filter water properly.

- Organic Matter: In areas with vegetation or organic materials (e.g., mulch, leaves), organic matter can clog the fabric. The accumulation of plant debris on top of or within the fabric fibers creates a barrier that prevents water from flowing freely.

- Excessive Sediment: Construction sites or areas prone to erosion can have high levels of sediment running through geotextiles. When there’s an excessive amount of fine sediment, it can infiltrate and clog the fabric, reducing its drainage capacity.

- Improper Installation: If the fabric is not installed properly or is exposed to high levels of stress during installation, it could be damaged. Damaged or poorly installed fabric is more susceptible to clogging because it can lose its structural integrity and filtration abilities.

- High Flow Conditions: If the flow of water passing through the geotextile is too fast or too forceful, it can carry with it larger particles that eventually become trapped in the fabric. This can be especially problematic in heavy rainfall conditions or areas with poor drainage infrastructure.

- Inadequate Maintenance: Failure to periodically inspect and maintain geotextile fabric can lead to the accumulation of dirt and debris, which can gradually reduce the material’s permeability.

Factors That Influence Clogging in Geotextile Fabric

The likelihood of geotextile fabric clogging depends on several factors, including:

- Type of Geotextile Fabric: The permeability and resistance to clogging differ between woven, nonwoven, and knitted geotextiles. Nonwoven geotextiles, for instance, are more prone to clogging due to their loose fiber structure. On the other hand, woven fabrics are generally stronger and have a lower risk of clogging, but they may have different filtration properties.

- Fabric Permeability: Permeability is one of the most important characteristics to consider when choosing geotextile fabric. A fabric with a higher permeability allows water to pass through more easily, but it can also let more sediment enter, increasing the risk of clogging. Fabrics with lower permeability might prevent sediment entry but could lead to water pooling and insufficient drainage.

- Type of Soil or Environment: The type of soil in which the fabric is placed has a direct impact on the potential for clogging. For instance, fine-grained soils like clay or silty soil can clog the geotextile more easily than coarser soils such as gravel or sand. Additionally, environments with a high amount of organic material (e.g., wetlands or areas with dense vegetation) may also contribute to clogging.

- Environmental Conditions: Areas with heavy rainfall or high sediment runoff can increase the chance of geotextile fabric clogging. Water carrying fine particles or debris can infiltrate the fabric and, over time, reduce its ability to filter properly.

Why Understanding Clogging Is Crucial

Knowing the causes and factors behind geotextile fabric clogging is essential because it helps in selecting the right type of fabric and implementing the proper installation and maintenance practices. Without addressing these issues early, you could face reduced drainage efficiency, structural damage, and potentially costly repairs or replacements of the fabric.

If you’re dealing with geotextile fabrics in areas prone to clogging, it’s vital to regularly check the fabric’s performance and address any signs of clogging before it becomes a major problem.

How to Prevent Geotextile Fabric from Clogging

Preventing geotextile fabric clogging requires a combination of proper installation, choosing the right fabric, and regular maintenance. By being proactive and implementing best practices, you can extend the lifespan of geotextile fabrics and ensure they continue to perform effectively. Below are several steps and techniques to prevent clogging and maximize the effectiveness of your geotextile fabric.

Proper Installation Techniques

The first line of defense against geotextile fabric clogging is ensuring proper installation. Even the best geotextile fabric will struggle to perform well if it is improperly installed. Here are some key installation tips:

- Ensure Proper Fabric Placement

- Flat and Level Surface: Make sure the fabric is laid flat and not wrinkled or stretched. Wrinkles or folds can trap sediment, leading to clogs.

- Avoid Direct Contact with Soil: Ideally, geotextile fabric should not come into direct contact with fine-grained soils (e.g., clay or silt), as these materials are more prone to clogging. Use gravel or coarse aggregate as a buffer between the fabric and fine soils.

- Use Multiple Layers for Protection

- If you’re using geotextile fabric for filtration or drainage, consider layering it with coarse materials (such as gravel or stone) on top. This creates a barrier that prevents soil and debris from reaching the fabric while still allowing water to pass through.

- Overlap Fabric Edges

- When installing multiple sheets of geotextile fabric, ensure that the edges overlap by at least 12-18 inches. This prevents soil from entering the gaps between fabric sheets and causing localized clogging.

- Avoid Compression

- Don’t compress the fabric too tightly during installation, as this can reduce its permeability. Ensure the fabric has enough space to allow water to flow freely through it.

- Seal and Protect the Edges

- Use appropriate sealants or fasteners to secure the edges of the fabric, preventing soil, debris, or water from infiltrating the fabric along the edges.

Use of Geotextile Fabric with Proper Permeability

Selecting the right type of geotextile fabric for your specific application is essential in preventing clogging. Geotextile fabric permeability plays a significant role in how well the fabric can filter water without clogging.

- Choose the Right Fabric for the Environment

- High-permeability Fabrics: If you’re working in an environment with low sediment levels (e.g., clear water runoff), choose a high-permeability fabric that will allow more water flow. However, keep in mind that higher permeability fabrics are more prone to clogging in areas with fine soil particles.

- Low-permeability Fabrics: For applications where fine-grained soils (such as clay or silt) are present, a low-permeability geotextile may be beneficial to limit the amount of sediment that passes through. However, these fabrics must be chosen carefully to avoid reduced water flow.

- Geotextiles with Built-in Filtration Layers

- Some geotextiles come with built-in filtration layers or advanced composite structures, such as geocomposites, which combine geotextiles with drainage cores. These fabrics are more resistant to clogging and often last longer in high-sediment environments.

- Use Synthetic or Non-biodegradable Materials

- Geotextiles made from polypropylene or polyester tend to be more durable and resistant to clogging than natural fibers like jute or coir. Choose synthetic geotextiles for long-term use in high-stress environments.

Maintaining Proper Drainage Systems

Ensuring that water flows freely through geotextile fabric is essential for preventing clogging. When water cannot move through the fabric as intended, it may accumulate and cause pressure on the fabric, forcing soil particles into the fibers and potentially leading to clogging.

- Ensure Proper Slope and Drainage

- For drainage systems, ensure that the area where the fabric is installed has a slight slope. This encourages water flow and prevents stagnant water that can clog the fabric. Proper drainage helps keep the fabric free from accumulating sediment.

- Install Drainage Pipes When Necessary

- In areas where water accumulation is likely, installing perforated pipes in conjunction with the geotextile fabric can help maintain consistent water flow. These pipes will allow excess water to escape while preventing sediment from entering the fabric.

- Use of Gravel or Aggregate Layers

- Placing a layer of gravel or other coarse aggregates over the geotextile fabric is a good practice in areas prone to heavy sediment or soil movement. This helps prevent fine particles from entering the fabric while still allowing water to pass through.

Regular Inspections and Maintenance

While geotextile fabric clogging can often be prevented with proper installation and choice of fabric, it’s still important to regularly inspect and maintain the fabric to ensure it continues to perform at its best. Periodic maintenance will help catch any potential clogging issues early on and prevent larger problems in the future.

- Inspect Fabric for Damage

- Over time, geotextile fabric can become damaged due to environmental factors such as UV degradation, physical wear, or extreme weather conditions. Inspect the fabric for any visible tears, holes, or signs of degradation that might allow soil or debris to penetrate.

- Look for Signs of Clogging

- Pooling Water: If you notice water pooling above the geotextile fabric, it could indicate that the fabric is clogged and water is not passing through properly.

- Slower Drainage: If water is draining more slowly than expected, this could also be a sign that sediment or organic material has built up inside the fabric fibers.

- Visual Inspection: Periodically lift small sections of the fabric to check for sediment build-up underneath. This can provide an early warning of potential clogging.

- Clean the Geotextile Fabric When Necessary

- Backflushing: In areas with heavy sedimentation, backflushing (flushing water through the fabric in reverse) can help clear out clogging materials.

- Pressure Washing: For certain types of geotextile fabrics, pressure washing may help clear out accumulated soil and debris. However, be cautious not to damage the fabric with high pressure.

- Removal and Replacement: In cases where the fabric has become severely clogged or damaged, removal and replacement may be necessary to restore the system’s function.

- Control Sediment and Debris

- Vegetation Control: In landscaping or erosion control applications, controlling vegetation around geotextile installations can help prevent organic matter from accumulating on the fabric. Regular maintenance such as trimming vegetation or removing debris is essential to keep the fabric clear.

What Happens When Geotextile Fabric Clogs?

Even with the best preventive measures, sometimes geotextile fabrics can become clogged. Understanding what happens when this occurs—and the consequences that may follow—is crucial for anyone using these materials. When geotextile fabrics clog, they can no longer effectively perform the functions they were designed for, which can lead to a range of problems, including poor drainage, increased erosion, and even structural failure.

Impact on Drainage and Water Flow

One of the primary purposes of geotextile fabric is to facilitate proper water flow by allowing water to pass through while filtering out sediment. When geotextile fabric clogs, it significantly hinders this process, which can lead to several serious drainage issues:

- Reduced Water Flow: As the fabric becomes clogged with sediment or organic material, its permeability is compromised. This means water can no longer pass through at the intended rate, leading to pooling or ponding in areas where drainage is essential.

- Waterlogging: In drainage systems, clogged geotextile fabric can cause water to accumulate, especially in areas that are supposed to be drained. This waterlogging can suffocate plant roots, reduce soil fertility, and compromise the structural integrity of roads or foundations.

- Increased Erosion: For erosion control applications, geotextile fabric clogging can exacerbate erosion problems. As the fabric becomes clogged, water may find new paths to flow, eroding the soil around the fabric and potentially destabilizing the area.

Potential Structural Damage

When geotextile fabric clogs in applications like road construction, foundation reinforcement, or landscaping, it can cause long-term damage to structures and foundations. The primary structural issues caused by clogged geotextiles include:

- Unstable Foundations: Geotextiles are often used to provide support and reinforcement for foundations. When the fabric becomes clogged, its ability to stabilize the underlying soil diminishes, leading to potential subsidence or settling of the structure above.

- Paving and Roadway Damage: In road construction, geotextile fabrics are used to distribute load and improve the strength of the roadbed. If the fabric becomes clogged and water cannot properly drain, the roadbed may weaken, leading to cracks, potholes, or even collapse in extreme cases.

- Damage to Embankments: For projects involving embankments or retaining walls, clogged geotextiles can lead to increased water pressure behind the structure. This pressure can weaken the wall or embankment, potentially causing it to fail over time.

- Soil Instability: Clogged geotextiles can cause water to back up or pool around the fabric, creating areas of saturated soil that can easily erode or become unstable. This is particularly concerning in sensitive environmental areas where soil stability is critical.

Costly Repairs and Replacements

Ignoring the potential for geotextile fabric clogging or failing to maintain the fabric properly can lead to significant costs in repairs and replacements. Here’s why:

- Removal and Replacement Costs: If geotextile fabric becomes heavily clogged and damaged, it may need to be removed and replaced entirely. The process of tearing out old fabric and installing new material can be labor-intensive, time-consuming, and expensive, especially if the fabric is embedded in a large construction or landscaping project.

- Damage to Surrounding Infrastructure: When clogged geotextiles lead to issues like waterlogging, erosion, or structural failure, the damage can extend beyond the fabric itself. For instance, roads, landscaping, or building foundations may require extensive repair work, resulting in even greater costs.

- Operational Downtime: In construction or infrastructure projects, clogged geotextiles may cause delays while repairs are made. This downtime can have a significant financial impact, especially on large projects with tight timelines.

- Long-Term Efficiency Losses: Even if the clogging isn’t immediately catastrophic, over time, geotextile fabric clogging reduces the efficiency of the drainage or filtration system. The result is ongoing operational inefficiencies that require more resources to maintain, ultimately leading to higher long-term costs.

Why Preventing Clogging Is Essential

Given the severe consequences of geotextile fabric clogging, it’s clear why regular maintenance and proper installation are crucial. Clogged fabric can quickly lead to system failures that are costly and time-consuming to fix.

In addition to the immediate issues, ignoring geotextile fabric clogging can cause long-term damage to your projects. Ensuring that the fabric remains unclogged will improve the efficiency of drainage systems, enhance soil stability, and prolong the lifespan of your construction, landscaping, or erosion control projects.

Case Study: Road Construction and Geotextile Fabric Clogging

In a real-life example, a highway construction project in a coastal region relied on geotextile fabric for stabilization and drainage. However, after several years of use, the fabric in some areas became clogged with silt and organic matter due to improper installation and insufficient drainage maintenance. The result? Water began pooling along the sides of the road, weakening the subgrade and causing roadbed instability.

The situation worsened when localized areas of the roadbed began to subside, leading to cracks and, eventually, large potholes. The repairs were extensive, requiring the replacement of the geotextile fabric, regrading of the roadbed, and even the resurfacing of large sections of the highway. In the end, the project incurred thousands of dollars in repairs and delays—an expense that could have been avoided with proper installation and regular maintenance.

The Long-Term Impact of Geotextile Fabric Clogging

When geotextile fabrics clog, the results can be far-reaching and costly. From poor drainage to structural failure and the need for expensive repairs, clogged fabric can affect the overall success of your project. Therefore, understanding the causes of clogging, taking preventive measures, and maintaining the fabric regularly are critical steps to ensuring that geotextile fabrics continue to function as intended.

By addressing these issues early and following best practices, you can prevent clogged fabric from becoming a major problem. This proactive approach will save you time, money, and effort, ensuring that your geotextile installations remain effective for years to come.