Geotextile fabric is an essential material in modern construction, landscaping, and civil engineering projects. Known for its versatility and durability, it is often used to stabilize soil, prevent erosion, and improve drainage. But a critical question frequently arises when selecting materials for these projects: Is geotextile fabric porous?

Understanding the porosity of geotextile fabric is crucial because it directly impacts its effectiveness in applications like drainage systems, road construction, and erosion control. Whether you are a contractor, landscaper, or a DIY enthusiast working on a backyard project, knowing how geotextile fabrics work—and specifically, whether they allow water and air to pass through—can help you make informed decisions.

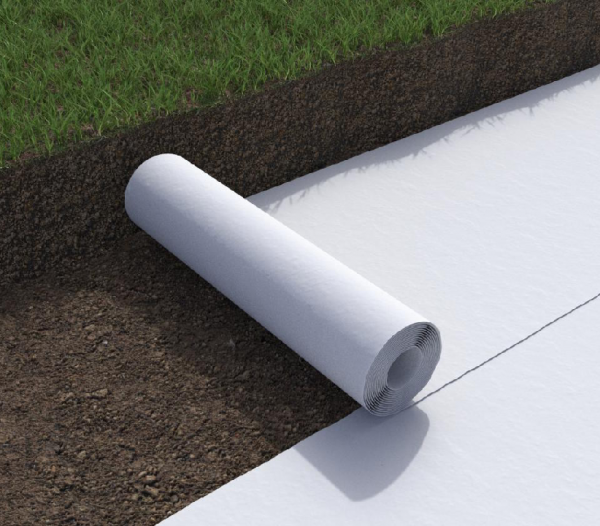

Geotextile fabric is a specialized material designed to be used in civil engineering, construction, and landscaping projects. It is primarily used to improve soil stability, provide erosion control, and enhance drainage systems. These fabrics are created by weaving or bonding synthetic or natural fibers to produce sheets of varying strengths and porosity levels.

The adaptability of geotextile fabric makes it a go-to solution for challenges in soil reinforcement and water management. For example, they are commonly found beneath roads, embankments, retaining walls, and even in gardens where proper drainage is critical. Their ability to address multiple functional requirements has earned them the nickname “the backbone of modern infrastructure.”

Types of Geotextile Fabrics

There are several types of geotextile fabrics, each tailored to specific applications. Here’s a breakdown:

- Woven Geotextiles:

- Description: Created by weaving fibers together, these fabrics are strong and durable.

- Applications: Ideal for heavy-duty projects like road stabilization and embankment support.

- Porosity: Generally less porous, designed for structural integrity.

- Non-Woven Geotextiles:

- Description: Manufactured by bonding fibers through heat or chemical processes.

- Applications: Often used for filtration and drainage due to their high porosity.

- Porosity: Highly porous, allowing water and air to pass through freely.

- Biodegradable Geotextiles:

- Description: Made from natural fibers like jute or coir, these fabrics decompose over time.

- Applications: Used in temporary erosion control projects or environmentally sensitive areas.

- Porosity: Can vary but generally allows water infiltration to aid plant growth.

Materials Used in Geotextile Fabrics

The performance of geotextile fabric largely depends on the material used in its manufacturing. Common materials include:

- Polypropylene: Known for its strength, lightweight properties, and resistance to chemicals.

- Polyester: Offers excellent durability and UV resistance.

- Natural Fibers: Materials like jute and coir provide eco-friendly options for short-term projects.

Why Understanding Geotextile Porosity is Important

Porosity determines how water, air, and fine particles interact with the fabric. Selecting a fabric with the right porosity is critical to ensuring that your project succeeds. For example, a drainage system requires a fabric that allows water to pass through but traps soil particles, while erosion control may need a balance between strength and permeability.

Understanding Porosity in Materials

What Does Porous Mean?

Porosity refers to the presence of tiny holes or spaces within a material that allow liquids, gases, or fine particles to pass through. In simpler terms, a porous material has a network of pathways that permit movement. The degree of porosity can vary significantly between materials, ranging from highly porous, like sponges, to non-porous, like glass.

For geotextile fabrics, porosity is an essential feature. It directly affects their ability to manage water flow, retain soil, and support plant growth. A fabric’s porosity is determined by its manufacturing process, the type of fibers used, and its intended application.

Why is Porosity Important in Construction and Landscaping?

The porosity of a material plays a critical role in its performance for specific tasks. In the context of construction and landscaping, here’s why it matters:

- Water Filtration:

Porous geotextile fabrics act as filters, allowing water to flow through while trapping sediment and debris. This makes them essential in drainage systems like French drains and retaining walls. - Soil Stabilization:

Porous materials help retain fine soil particles while allowing excess water to escape. This prevents soil displacement and enhances structural stability in applications like roads and embankments. - Erosion Control:

By maintaining a balance between water permeability and soil retention, porous fabrics protect against soil erosion, especially on slopes or riverbanks. - Air Movement:

In landscaping, porous fabrics enable air circulation in the soil, which promotes healthy root development and plant growth.

Porosity: A Measurable Attribute

Porosity is typically expressed as a percentage and can be measured using specialized testing. Factors influencing a geotextile fabric’s porosity include:

- Pore Size Distribution: The range of pore sizes in the fabric determines what particles can pass through.

- Permeability: Refers to the rate at which water or air can pass through the fabric, often measured in liters per second.

For example, non-woven geotextiles often have a higher permeability rate than woven types, making them ideal for drainage-focused projects.

The Role of Porosity in Geotextile Fabrics

Porosity is a design feature, not a flaw. Engineers and manufacturers adjust the porosity of geotextile fabrics to meet specific project needs. Some fabrics are engineered to maximize water flow (high porosity), while others prioritize soil retention and structural integrity (low porosity).

Is Geotextile Fabric Porous?

Answering the Core Question

Yes, geotextile fabric is porous, but the degree of porosity varies significantly depending on the type and design of the fabric. The porosity of geotextile fabric allows it to perform critical functions such as filtration, drainage, and soil stabilization. Its ability to allow water and air to pass through while blocking solid particles makes it a versatile material in both construction and landscaping applications.

Types of Porosity in Geotextile Fabrics

- Permeable Geotextiles:

- These fabrics are designed to allow the free flow of water and air.

- Commonly used in drainage systems and filtration applications.

- Example: Non-woven geotextiles, which are known for their high permeability.

- Semi-Permeable Geotextiles:

- These fabrics restrict water flow to a controlled level while retaining structural strength.

- Often used in soil reinforcement or erosion control projects.

- Example: Woven geotextiles, which are less porous but offer superior strength.

- Customized Porosity:

- Some geotextiles are engineered to meet specific project requirements, with pore sizes tailored to filter certain materials while allowing others to pass.

How Porosity Varies Between Fabric Types

Geotextile fabrics are classified into woven and non-woven types, each with distinct porosity characteristics:

- Woven Geotextiles:

These fabrics are made by weaving threads together, resulting in a tight structure. While they are less porous compared to non-woven geotextiles, their strength makes them ideal for applications requiring load distribution and soil reinforcement, such as road stabilization projects. - Non-Woven Geotextiles:

These fabrics are manufactured using heat-bonding, needle-punching, or other processes to create a random network of fibers. Their porous nature allows water to pass through easily, making them suitable for drainage, filtration, and landscaping tasks.

| Fabric Type | Strength | Porosity | Common Applications |

|---|---|---|---|

| Woven | High | Low to Medium | Road stabilization, embankments |

| Non-Woven | Medium | High | Filtration, drainage, landscaping |

Real-World Examples of Porous Geotextiles

- French Drain Systems:

Porous geotextiles are used to line drainage trenches. They allow water to flow freely into the drain while preventing soil from clogging the system. - Retaining Walls:

Geotextile fabrics placed behind retaining walls improve drainage by allowing water to escape without displacing the backfill material. - Landscaping Projects:

Non-woven geotextiles help maintain proper soil moisture levels in gardens by facilitating water movement while blocking unwanted debris.

Benefits of Porosity in Geotextile Fabrics

The porosity of geotextile fabric is not just a feature—it’s a critical advantage that underpins its usefulness in various industries. Key benefits include:

- Efficient Water Management: Ensures proper drainage and reduces the risk of waterlogging.

- Erosion Prevention: Protects soil from being washed away in high-flow areas.

- Enhanced Soil Stability: Supports load distribution by separating soil layers while maintaining permeability.

Benefits of Porosity in Geotextile Fabrics

The porosity of geotextile fabric is one of its defining features, enabling it to perform a range of essential functions in construction, landscaping, and environmental projects. Below, we’ll delve into the key benefits that make porous geotextiles a vital material across various applications.

1. Efficient Water Filtration

Porous geotextile fabrics are designed to allow water to flow through while capturing sediment and debris. This dual function makes them an integral part of drainage and filtration systems.

- In Drainage Applications:

In French drains and subsurface systems, porous fabrics prevent soil particles from clogging the drainage pipes, ensuring long-term functionality. - In Water Retention Systems:

Geotextiles help control water flow in areas prone to waterlogging, balancing moisture levels in the soil.

Example:

A non-woven geotextile fabric placed beneath a gravel driveway helps filter stormwater runoff while stabilizing the gravel layer.

2. Erosion Control

Porous geotextiles act as a barrier to soil movement, reducing erosion on slopes, riverbanks, and other areas prone to water flow. The fabric allows water to pass through without washing away soil particles, preserving the land’s integrity.

- In Coastal Areas:

Porous fabrics are used to line sand dunes and embankments, preventing coastal erosion caused by wave action. - On Construction Sites:

Erosion control mats made of geotextile fabric stabilize soil during rainfall and prevent sediment runoff.

Data Insight:

Studies show that erosion is reduced by up to 60% when geotextile fabrics are applied on slopes compared to untreated areas.

3. Improved Airflow and Soil Health

The permeability of geotextile fabric supports airflow in soil, which is critical for maintaining healthy ecosystems in landscaping projects.

- Benefits for Plants:

Air circulation in the soil promotes robust root growth, reduces compaction, and prevents the development of anaerobic conditions that can harm plants. - In Landscaping and Gardening:

Porous geotextile fabrics are commonly used under mulch to separate soil from decorative layers while maintaining air and water exchange.

Fun Fact:

In urban green spaces, geotextiles are often incorporated beneath artificial turf to mimic the natural exchange of air and water found in soil.

4. Prevention of Soil Contamination

Porous geotextiles serve as separators between different soil layers, preventing contamination and preserving the integrity of the subgrade.

- In Road Construction:

These fabrics are used to separate fine subgrade soil from aggregate layers, maintaining the structural stability of roads over time. - In Environmental Projects:

Geotextiles are applied to encapsulate contaminated soils, allowing water to pass through while containing harmful particles.

5. Longevity and Cost Savings

While the initial investment in geotextile fabric may be higher than traditional materials, its porosity ensures superior performance and reduces maintenance costs.

- Durability:

The fabric’s ability to maintain its porous structure over time minimizes blockages and extends the lifespan of drainage and filtration systems. - Reduced Replacement Costs:

Porous geotextiles require less frequent replacement, saving both labor and material expenses in the long run.

Case Study:

A 10-year review of highway construction projects in the U.S. revealed that sections incorporating geotextile fabrics had 25% fewer maintenance issues compared to those without.

6. Environmental Benefits

The porosity of geotextile fabrics supports eco-friendly practices by promoting water conservation and reducing soil erosion, which helps protect natural ecosystems.

- In Rainwater Harvesting:

Porous fabrics aid in directing rainwater to collection systems while filtering out debris. - In Green Roofs:

Geotextiles in green roof systems improve drainage while supporting plant growth.

Porosity isn’t just a feature of geotextile fabrics—it’s their core strength. By allowing controlled movement of water and air while providing structural support, these fabrics excel in both performance and durability.