Geotextiles have become an essential component in modern civil engineering and construction projects. These versatile materials play a crucial role in improving the durability, sustainability, and cost-effectiveness of infrastructure developments. But what exactly are geotextiles, and what are they used for?

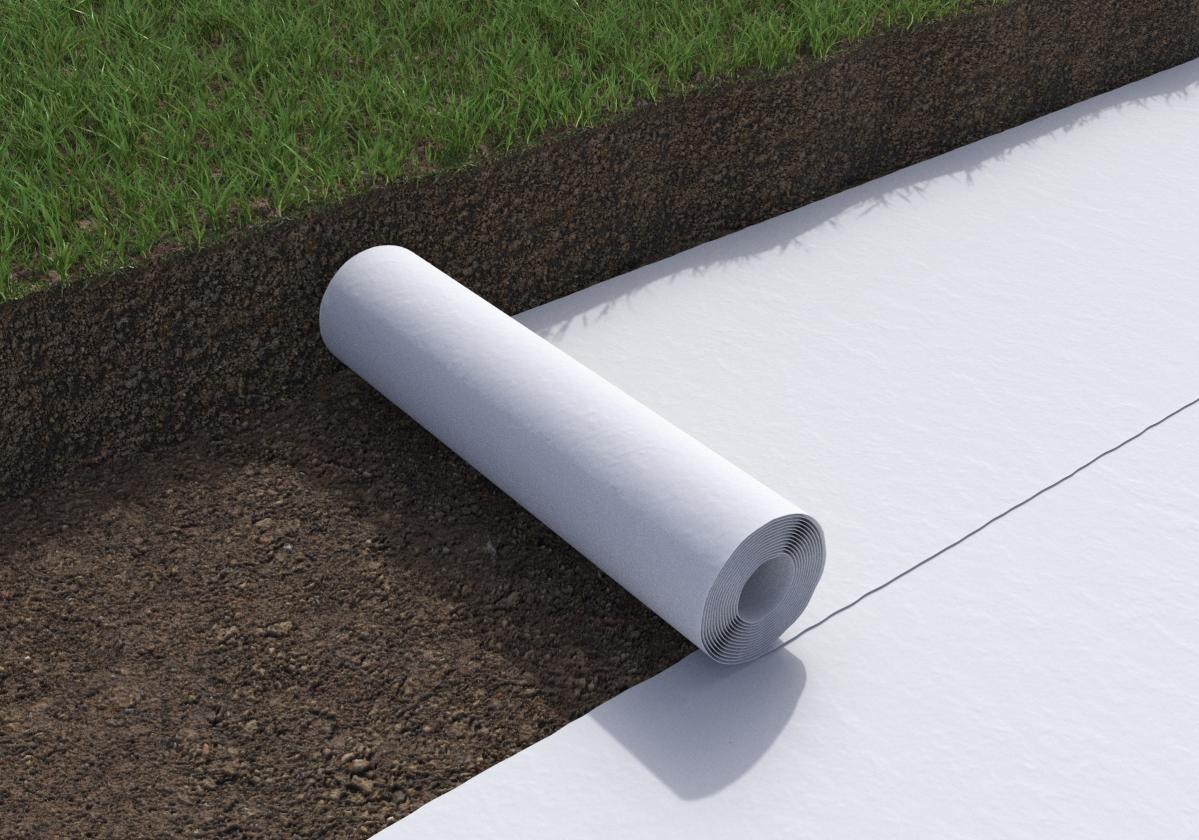

Geotextiles are permeable fabrics designed to be used in conjunction with soil, rock, or other construction materials to improve the performance and longevity of infrastructure. Made primarily from synthetic polymers such as polypropylene or polyester, geotextiles come in a variety of forms, including woven, non-woven, and knitted types, each tailored to specific applications.

The origin of geotextiles dates back to the 1950s when they were first developed as a solution to soil stabilization problems in large construction projects. Over the decades, geotextiles have evolved into a diverse class of materials with applications spanning roads, railways, drainage systems, and environmental protection.

Their functionality hinges on their permeability, strength, and resistance to environmental degradation, making them indispensable for modern infrastructure.

Why Are Geotextiles Important?

Geotextiles are vital due to their ability to enhance the performance of engineering structures while reducing the overall cost of construction and maintenance. Their importance can be summarized in the following key points:

- Durability and Strength: Geotextiles provide robust solutions to challenges like soil erosion, water drainage, and load-bearing in weak soils.

- Sustainability: By reducing the need for excessive raw materials (such as gravel or sand layers), geotextiles contribute to more environmentally friendly construction practices.

- Cost-Effectiveness: They minimize the frequency of repairs and maintenance, leading to significant long-term savings.

Additionally, their lightweight nature and ease of installation further contribute to their widespread adoption across various industries.

The 3 Main Uses of a Geotextile

Geotextiles are engineered for various purposes, but their three primary uses—separation, filtration, and reinforcement—form the foundation of their applications in construction and environmental management. Let’s explore each use in detail.

1. Separation

What is Separation?

Separation refers to the ability of geotextiles to prevent the mixing of different soil layers or materials, ensuring that each layer retains its integrity and functionality. This is especially critical in construction projects where the blending of soil types can compromise the structure’s stability and performance.

Applications of Geotextiles in Separation

- Road Construction: Geotextiles are often used between the subgrade and base course in road projects. By keeping the two layers distinct, they prevent the contamination of aggregate layers with fine soil particles, which can weaken the road’s foundation.

- Railway Tracks: In rail projects, geotextiles ensure that the ballast layer remains free of subsoil infiltration, maintaining track stability over time.

- Landfills: Geotextiles act as separators in landfill covers, isolating waste material from the top layers of soil or vegetation.

Benefits of Geotextiles for Separation

- Enhanced Structural Integrity: By preventing the intermixing of materials, geotextiles improve the load-bearing capacity of the structure.

- Reduced Maintenance Costs: Maintaining the distinct layers extends the life of roads, railways, and similar structures.

- Improved Efficiency: The separation provided by geotextiles allows for the use of specific materials optimized for their purpose, without contamination affecting their performance.

Case Study: Separation in Road Construction

In a recent highway project in Texas, geotextiles were deployed to stabilize the base layer and prevent soil intrusion into the aggregate. Over a five-year period, roads with geotextile integration reported a 35% reduction in maintenance costs compared to conventional methods. This demonstrates the effectiveness of geotextiles in enhancing structural longevity and cost-efficiency.

2. Filtration

What is Filtration?

Filtration involves allowing water or other fluids to pass through the geotextile while retaining soil or particulate matter. This function is particularly important in managing water flow in drainage systems and preventing erosion.

Applications of Geotextiles in Filtration

- Drainage Systems: Geotextiles are placed around drainage pipes to filter out sediment while allowing water to flow freely, reducing the risk of clogging.

- Erosion Control: On slopes, riverbanks, and coastal areas, geotextiles help manage water flow, preventing soil erosion while allowing natural seepage.

- Retaining Walls: Geotextiles ensure water drainage in retaining walls, reducing hydrostatic pressure and increasing structural stability.

Benefits of Geotextiles for Filtration

- Clog Prevention: By filtering out fine particles, geotextiles keep drainage systems functional for longer periods.

- Improved Water Management: They facilitate proper water flow in areas prone to flooding or waterlogging.

- Environmental Protection: Geotextiles help prevent soil loss, contributing to sustainable land management.

Data Insight: Geotextiles in Drainage

Studies show that geotextile-integrated drainage systems last 25-30% longer than traditional methods without filtration layers, reducing both environmental impact and maintenance costs.

3. Reinforcement

What is Reinforcement?

Reinforcement is the process of using geotextiles to improve the load-bearing capacity and stability of weak or unstable soils. By acting as a tensile member, geotextiles distribute loads more evenly and enhance the mechanical strength of the soil structure.

Applications of Geotextiles in Reinforcement

- Retaining Walls: Geotextiles are placed in layers within soil to provide additional tensile strength, preventing structural collapse.

- Embankments and Slopes: When used in embankment construction, geotextiles stabilize the foundation, even on weak or waterlogged soils.

- Foundations on Soft Soil: Geotextiles help spread load evenly, enabling the construction of buildings or roadways on poor soil conditions.

Benefits of Geotextiles for Reinforcement

- Increased Load-Bearing Capacity: By reinforcing the soil, geotextiles enable the construction of structures that can withstand heavier loads.

- Improved Stability: They reduce the risk of landslides and slope failures in challenging terrains.

- Cost Savings: Geotextile reinforcement often eliminates the need for expensive soil replacement or additional foundation work.

Case Study: Reinforcing a Levee System in the Netherlands

In a flood-prone area of the Netherlands, geotextiles were used to reinforce levees protecting nearby communities. The materials provided critical support to the soft soil foundation, reducing the risk of collapse during heavy rains. After implementation, the levees successfully withstood multiple severe weather events, and maintenance costs dropped by 40% over a decade.

Comparison of Geotextile Types for Reinforcement

| Type | Best Suited For | Key Advantages |

|---|---|---|

| Woven Geotextiles | High-tensile reinforcement | Strength and durability |

| Non-Woven Geotextiles | Foundations with drainage needs | Flexibility and filtration capability |

| Knitted Geotextiles | Specialized reinforcement | Customized for unique applications |

Geotextile reinforcement is a cornerstone of modern construction, providing solutions for building durable, cost-effective infrastructure on challenging terrain.

Types of Geotextiles and Their Applications

Geotextiles come in various types, each designed to address specific challenges in construction and environmental management. Understanding the differences between these types is essential for selecting the right material for a project. The three primary types of geotextiles are woven, non-woven, and knitted, and each has unique characteristics and applications.

Woven Geotextiles

Overview

Woven geotextiles are made by interlacing synthetic fibers in a weave pattern, creating a strong and durable fabric. These geotextiles are characterized by their high tensile strength, making them ideal for projects requiring reinforcement and separation.

Applications of Woven Geotextiles

- Road Construction: Used to stabilize subgrades and reinforce pavements.

- Railway Tracks: Prevents ballast contamination while offering structural support.

- Erosion Control: Commonly used in retaining structures to mitigate soil erosion.

Advantages of Woven Geotextiles

- High durability and resistance to deformation under heavy loads.

- Excellent performance in applications requiring long-term reinforcement.

- Reduced costs due to material efficiency in demanding projects.

Example

In a major highway project in India, woven geotextiles were used to stabilize the road base. The project achieved 30% cost savings due to the reduction in aggregate requirements and improved road performance over time.

Non-Woven Geotextiles

Overview

Non-woven geotextiles are manufactured using heat bonding or needle punching processes to create a flexible, felt-like fabric. These geotextiles are highly permeable, making them ideal for filtration and drainage applications.

Applications of Non-Woven Geotextiles

- Drainage Systems: Acts as a filter in drainage pipes and trenches.

- Landfills: Serves as a barrier to prevent soil contamination while allowing water to drain.

- Slope Stabilization: Protects against erosion while managing water flow.

Advantages of Non-Woven Geotextiles

- Superior water permeability for effective filtration.

- Flexible and easy to install, even in irregular terrain.

- Can combine drainage and reinforcement functions in certain applications.

Comparison to Woven Geotextiles

Non-woven geotextiles may not have the same tensile strength as woven types, but they excel in water management and adaptability, particularly in areas with complex hydraulic conditions.

Knitted Geotextiles

Overview

Knitted geotextiles are less common and are made by knitting synthetic fibers into a fabric structure. They are often tailored for specialized applications requiring unique properties.

Applications of Knitted Geotextiles

- Reinforcement in Coastal Structures: Provides stability to sea walls and breakwaters.

- Custom Engineering Solutions: Used in projects requiring precise material behavior.

Advantages of Knitted Geotextiles

- Customizable for specific engineering challenges.

- Combines strength with flexibility for versatile applications.

Use Case

Knitted geotextiles were employed in a coastal reclamation project in Malaysia, where their tailored design provided reinforcement to sandy soils, enabling successful land development in an area prone to erosion.

Comparison Table of Geotextile Types

| Type | Strength | Permeability | Best Use |

|---|---|---|---|

| Woven Geotextiles | High tensile strength | Moderate | Reinforcement, separation |

| Non-Woven Geotextiles | Moderate strength | High | Filtration, drainage |

| Knitted Geotextiles | Customizable strength | Variable | Specialized applications |

Selecting the right type of geotextile depends on the specific project requirements, including soil conditions, hydraulic demands, and intended function.

Benefits of Using Geotextiles

Geotextiles have transformed the way infrastructure and environmental challenges are addressed, providing practical and cost-effective solutions across various industries. Their versatility and performance advantages make them indispensable in modern construction and engineering. Here, we’ll delve into the key benefits of geotextiles, focusing on their environmental, economic, and structural impacts.

Environmental Benefits

- Erosion Control

Geotextiles help manage soil stability, especially in areas prone to erosion, such as slopes, riverbanks, and coastal regions. By acting as a protective barrier, they prevent soil loss while allowing water to pass through naturally.- Example: In coastal restoration projects, geotextiles reduce sediment displacement, preserving habitats and mitigating environmental damage.

- Sustainable Construction

By reducing the reliance on excessive natural resources like gravel and sand layers, geotextiles contribute to more sustainable construction practices. Many geotextiles are also recyclable, further enhancing their eco-friendliness.- Fact: Studies show geotextiles can reduce the volume of aggregate materials required in construction by up to 50%, significantly lowering the environmental footprint.

- Water Management

Geotextiles facilitate controlled water flow, reducing risks of flooding and waterlogging. This helps protect ecosystems while supporting long-term land management.

Economic Benefits

- Cost Savings in Construction

The integration of geotextiles reduces the need for thick layers of expensive fill materials, saving money during the initial construction phase.- Stat: Roads built with geotextiles can cut costs by 25-40% compared to conventional methods, thanks to reduced material requirements and extended road life.

- Lower Maintenance Costs

Geotextiles enhance the durability of structures, reducing the need for frequent repairs.- Case Study: A railway project in Europe reported a 35% decrease in maintenance costs over a 10-year period after incorporating geotextiles for ballast stabilization.

- Longevity of Infrastructure

By improving load distribution and preventing structural failures, geotextiles significantly extend the lifespan of roads, buildings, and drainage systems.

Structural Benefits

- Enhanced Soil Stability

Geotextiles strengthen weak or unstable soils, enabling the construction of projects on challenging terrains.- Example: Retaining walls reinforced with geotextiles can withstand higher loads and resist failures in earthquake-prone areas.

- Increased Load-Bearing Capacity

By redistributing weight across a broader area, geotextiles ensure that infrastructure can handle heavy loads without deformation or collapse. - Versatility Across Applications

Whether used in roads, railways, embankments, or drainage systems, geotextiles offer a flexible solution that adapts to the needs of each project.

Summary of Geotextile Benefits

| Category | Key Benefits |

|---|---|

| Environmental | Erosion control, sustainable material use, water management |

| Economic | Lower construction costs, reduced maintenance expenses |

| Structural | Improved soil stability, enhanced load capacity, adaptability |

Geotextiles not only provide immediate functional advantages but also deliver long-term benefits that save resources, reduce environmental impact, and ensure project success.